HRI4PCA SPEAKER BIOS AND ABSTRACTS

ALISA ANDRASEK

AI-powered transformation of AEC and cities with new design workflows built on principles of complexity. Synthesis of big data from a multitude of sources enabling context-sensitive and integrated systems within an information-rich simulation. A new frontier of creativity emerging at the threshold between humans increasingly attuned to new sensibilities excited by the machinic paradigm, and machines becoming increasingly organic. Applications include AI high rising typologies synthesized with local data and computational physics, context-sensitive models for high-density residential clusters, big data and AI-driven synthesis for green energy infrastructure, and AI combinatorics for increasing variability of CLT prefabrication.

Alisa Andrasek, Cloud Pergola, Croatian Pavilion at the Venice Architectural Biennale 2018.

Bio

Dr. Alisa Andrasek is working on the convergence of design, computer science and exponential technologies. She is bringing AI and robotics to the forefront of architectural design and construction. The founder of Biothing and AIARCH, a partner of Bloom Games, and co-founder of AI Build, Andrasek is Professor of Design Innovation at RMIT, prior to which she directed an award winning program in advanced architectural design at UCL in London and Wonderlab research. Her work has been exhibited at the Centre Pompidou Paris, New Museum NY, Storefront NY, FRAC Collection Orleans, TB-A21 Vienna, Beijing and Sydney Biennial, among others.

BRIAN RINGLEY

The vast majority of construction projects are delivered behind schedule and over budget. More effective jobsite management requires comprehensive visibility, but holistic site monitoring is infeasible with human labor, fixed sensor systems, or ground robot wheeled/tracked locomotion. Through legged mobility and flexible, whole-building autonomous navigation systems, agile mobile robots are enabling an unprecedented amount of data capture in dynamic, human-purposed environments. The integration of geospatial hardware, 5G telecommunications, cloud compute, and emerging AI for unstructured reality capture data into agile mobile robots is ushering in the scaled use of digital twins in construction. Twins are the key to establishing reality feedback loops into BIM delivery systems, accurately coupling the virtual and the real as a robot mapping and localization prerequisite for the broader use of heterogeneous robot fleets on construction sites.

Bio

Brian Ringley is a product manager at Boston Dynamics where he leads Spot product development for construction applications. Before coming to Boston Dynamics, he was a CNC programmer and machinist, practiced architecture as a design computation specialist, and piloted emerging construction robotics products and stood up a factory for industrialized construction as a construction automation researcher.

DANIELA MITTERBERGER

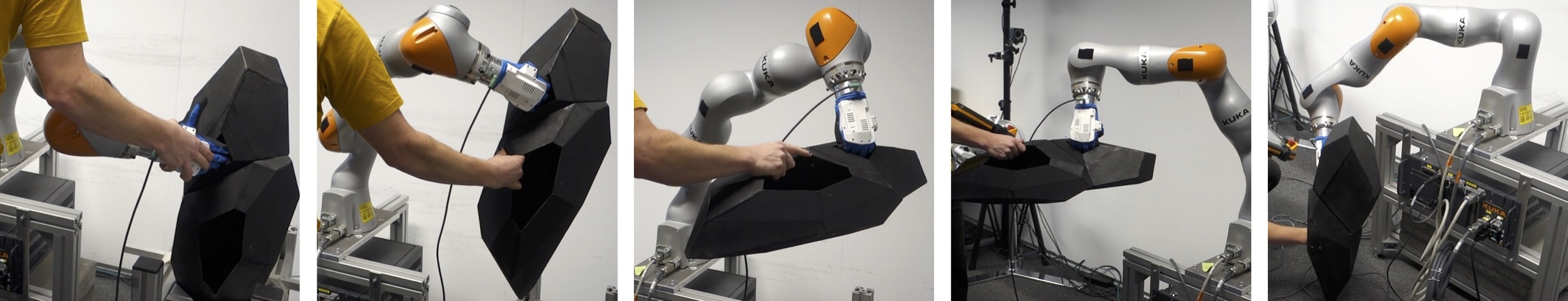

Human-machine collaboration in computational design and robotic fabrication

This research aims to explore and implement human-machine collaborative strategies in architecture, digital design, and robotic fabrication by combining implicit human knowledge with explicit decision-making processes of automated systems. As such, it focuses on novel human-augmentation strategies and tools needed for human-machine collaboration to perform non-standard fabrication tasks at full architectural scale. This project investigates how the cognitive abilities and tacit knowledge of humans can augment the precision, immediacy and speed of machine agents to enable otherwise either impossible or unsustainable tasks.

Co-corporeality – eye tracking device to control machines (© Zita Oberwalder)

Bio

Daniela Mitterberger is an architect and researcher with a strong interest in new media, the relationship between the Human/Body within digital fabrication, and emerging technologies. She is co-founder and director of MAEID, a multidisciplinary architecture practice based in Vienna. Currently, Daniela is a Ph.D. researcher at ETH Zürich at Gramazio Kohler Research, focusing on intuition in digital design and robotic fabrication. Daniela is also a researcher at the University of Applied Arts and co-leader of an FWF PEEK project titled “Co-corporeality”.

Her work has been recognized with several awards. It has been widely exhibited at various international galleries, institutions, and events, including Venice Biennale 2021, Ars Electronica Linz, Melbourne Triennial, Academy of Fine Arts Vienna, and HdA Graz.

HENRIETTE BIER

Advancing Robotics in Architecture

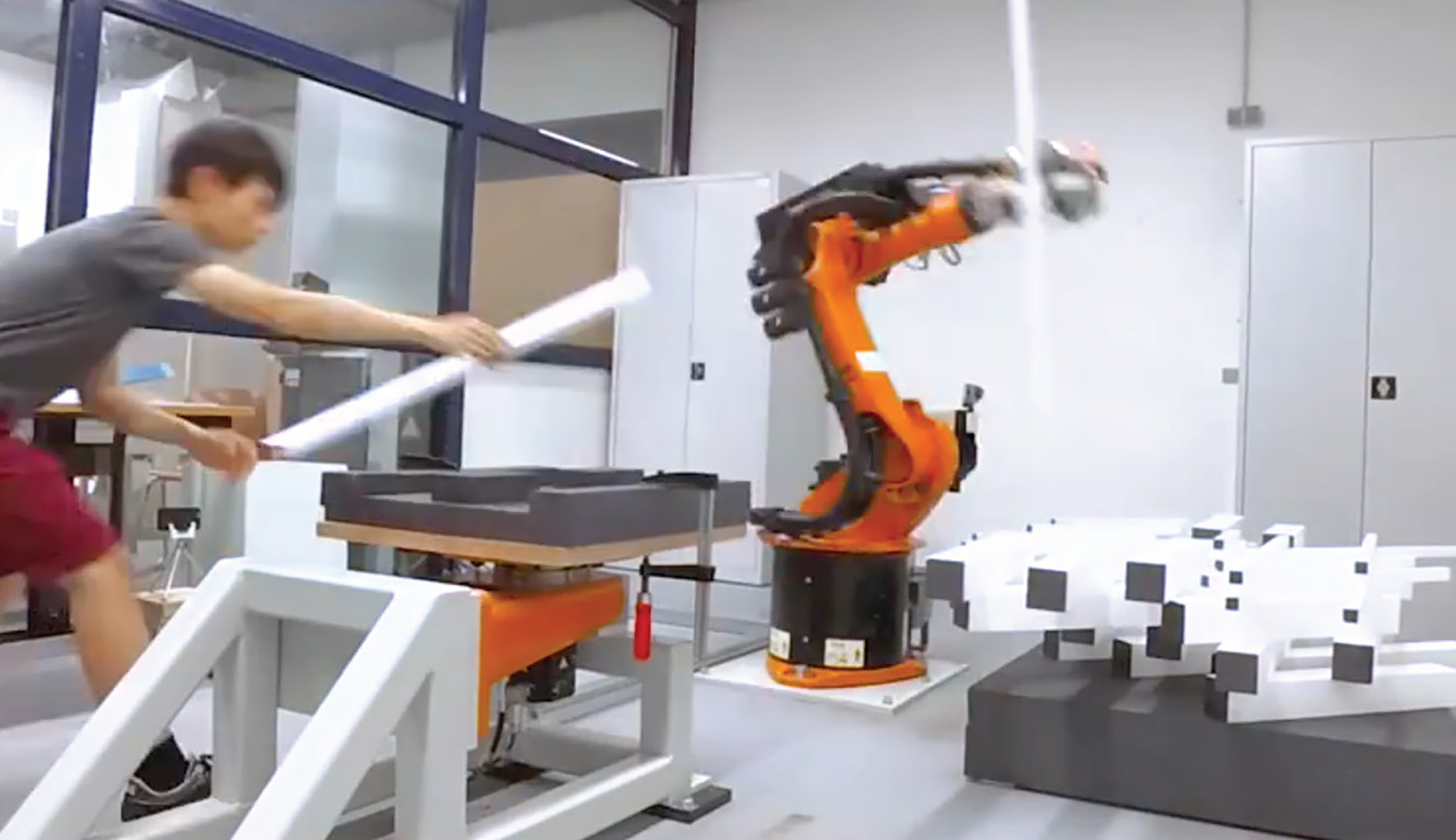

Knowing that more than 50% of tasks can and will be fully automated, while 45% rely on Human-Robot-Interaction (HRI), and only 5% remain in human hands, research into Design-to-Robotic-Production-Assembly and -Operation (D2RPA&O) advances robotics in architecture. It links efficiently computational design with robotic production, assembly, and operation and employs a customizable multi-robot and multi-effector approach relying on HRI. The ultimate goal is to facilitate an effective and safe physical interaction between robots and humans implementing complex tasks in order to establish the blueprint for next-generation building wherein robots and humans construct and operate buildings side by side.

Bio

Henriette Bier is initiator and leader of the Robotic Building lab at TUD, associate professor at TUD and founding member of the TU Delft Robotics Institute. She regularly lectures and leads workshops internationally and has been visiting professor at DIA (2017-19). Results of her research have been published and presented in more than 120 journals, books, and exhibits.

LUKA PETERNEL

Robots are very good at handling high physical workload, and can perform precise and fast movements, while human have superior cognitive capabilities and manual dexterity. The talk will present an approach of how to combine these attributes in physical human-robot collaboration for construction and other tasks. We govern the robot physical interaction with the human and environment by using methods based on impedance control principle, which enables compliant and safe operation. Higher level reasoning and communication between the human and the robot are handled by an artificial intelligence system based on machine learning methods and various sensory interfaces.

Bio

Luka Peternel received a Ph.D. in robotics from Faculty of Electrical Engineering, University of Ljubljana, Slovenia in 2015. He conducted his Ph.D. studies at Department for Automation, Biocybernetics and Robotics, Jožef Stefan Institute in Ljubljana from 2011 to 2015, and at the Department of Brain-Robot Interface, ATR Computational Neuroscience Laboratories in Kyoto, Japan in 2013 and 2014. He was with the Human-Robot Interfaces and Physical Interaction Lab, Advanced Robotics, Italian Institute of Technology in Genoa, Italy from 2015 to 2018. From 2019 he is an Assistant Professor at the Department of Cognitive Robotics, Delft University of Technology in the Netherlands.

LUKAS LACHMAYER

In ordinary cases, large-scale production, whether additive, subtractive or through forming, is realised by upscaled machinery. While this appears the easiest way to achieve required tolerances, such production systems lack flexibility, mobility and thus foil sustainability. Enabling mobile robots with infinite workspace to perform building tasks indicates a route for future production. Mainly developed for handling and transportation tasks manufacturing with mobile platforms or even multi-robot teams and collaboration offers numerous pending research missions.

Bio

Lukas Lachmayer is conducting his research as a mechanical engineer at the institute of assembly technology at the Leibniz University in Hannover. While initially developing machine tools and milling robots at DMG Mori and the institute of production engineering and machine tools, he now focuses on process control and path-planning for robot-based additive manufacturing processes. As part of the collaborative research program TRR 277, the goal is a holistic printing path generation regarding various process constraints such as material, robot capabilities and required component quality to ensure faultless 3D-printing processes.

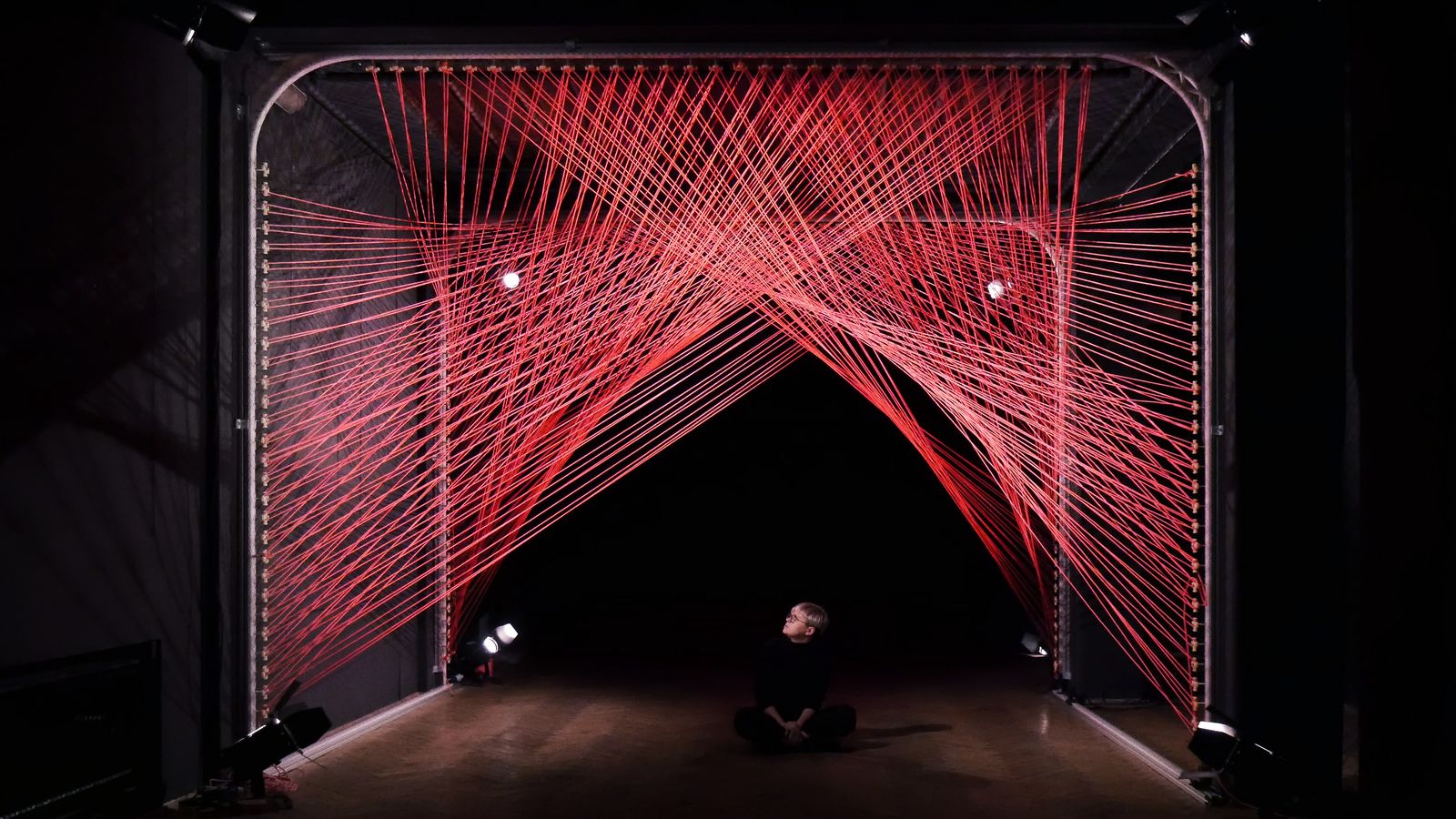

MARIA YABLONINA

Designing [with] Machines aims to investigate and establish design methodologies that consider robotic hardware development as part of the overall design process and its output. Through this work, a design practice emerges that moves beyond the design of objects towards the design of technologies and processes that enable new ways of both creating and interacting with architectural spaces. The practice specifically focuses on the development of task-and task-specific robotic devices and systems that are inherently suitable for in-situ fabrication as architectural intervention within the context of existing building stock.

Bio

Maria Yablonina is an architect, researcher, and artist working in the field of computational design and digital fabrication. Her work lies at the intersection of architecture and robotics, producing spaces and robotic systems that can construct themselves and change in real-time. Such architectural productions include the development of hardware and software solutions, as well as complementing architectural and material systems in order to offer new design spaces. Maria’s practice focuses on designing machines that make architecture — a practice that she broadly describes as Designing [with] Machines (D[w]M).

MIRCO BECKER

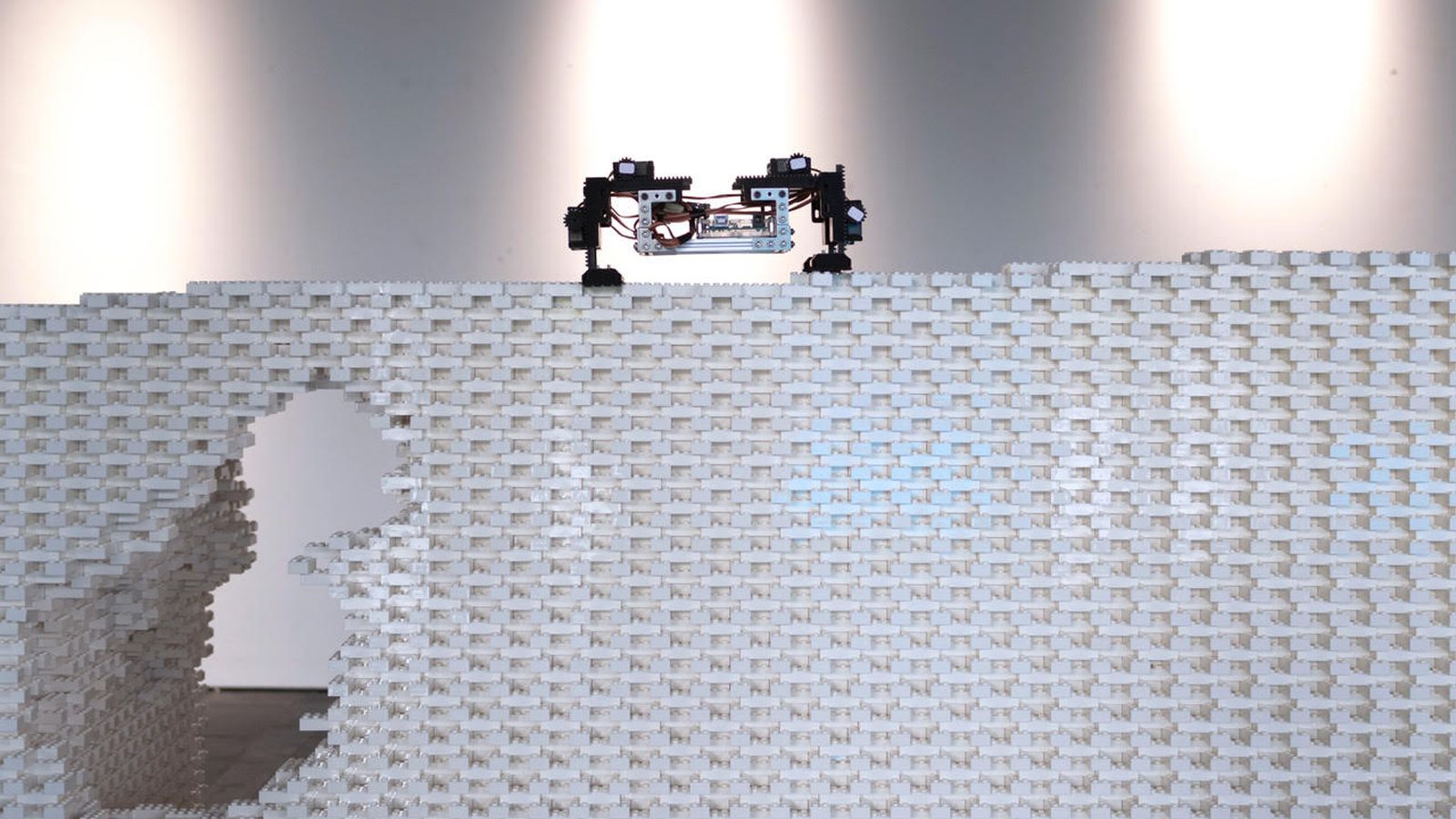

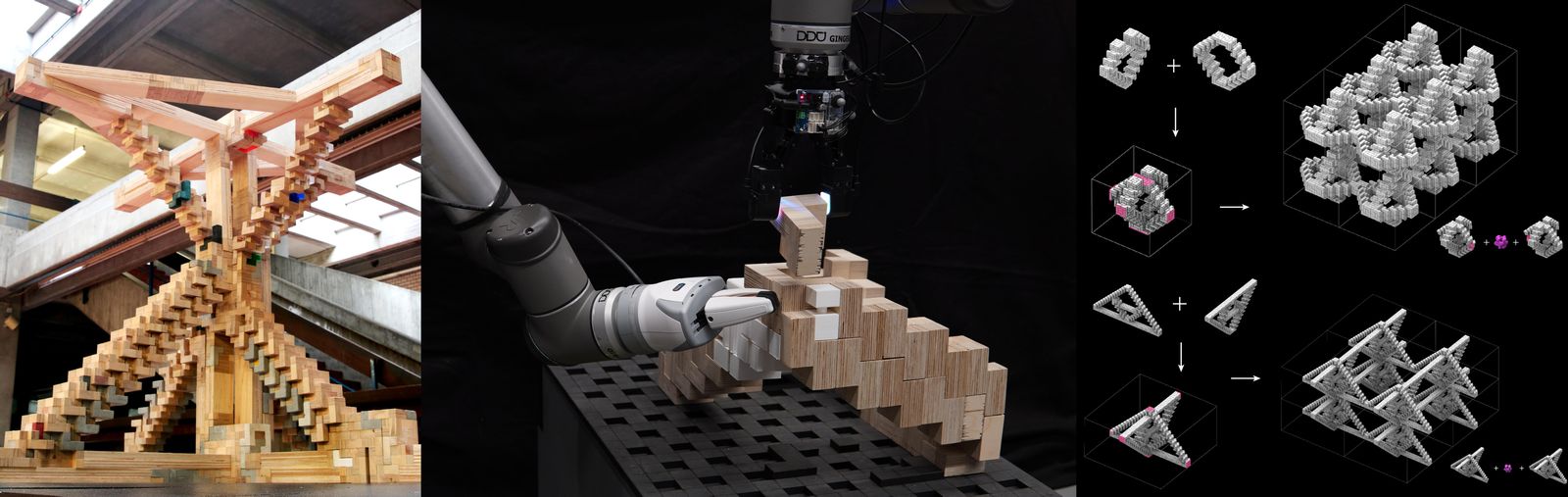

The transformation of the architectural construction ecosystem towards the integration of automated and autonomous machinery bears the potential to fundamentally reconsider the formats of construction material. At the same time, with the obligation of eliminating CO2 emissions from building materials, a change in the type of construction materials away from concrete and steel is paramount. On this backdrop the work presents the miniaturisation of construction material formats and thus miniaturising autonomous construction robots. In consequence these material blocks will stay in the build environment much longer than the lifespan of a single building. Made up of bio-based materials these blocks act as a carbon sink.

Bio

Prof. Mirco Becker holds the chair of Digital Methods in Architecture (dMA) at the Leibniz University Hannover since 2016. His research interest is in computational design and particularly the exploration of small-scale robots for architectural construction. From 2012-2016 he held a Stiftungsprofessor at the Städelschule Architecture Class, Frankfurt. He graduated from the AA Design Research Lab in 2003. His expertise in computational design was developed and applied with with Zaha Hadid Architects, Foster & Partners Specialist Modelling Group, and Kohn Pedersen Fox Computational Geometry Group which he led from 2005 for 5 years as a Senior Associate Principal.

OLIVER TESSMANN

The project Tactile Robotic Assembly explores autonomous assembly of modular constructions conducted by AI-driven robots equipped with visio-tactile sensors. Dry-jointed and reversible elements allow for their assembly, dis-assembly and re-assembly in a circular fashion. The project aims at shifting the Human-Robot Interaction away from immediate collaboration. Humans rather demonstrate movements that the robot seeks to mimic and improve through machine learning. While robots build, humans shape and refine the rewards of the machine learning algorithms and design architectural elements suitable for robotic assembly.

Bio

Oliver Tessmann is an architect and professor at the Technical University of Darmstadt where he is heading the Digital Design Unit (DDU). His teaching and research revolves around computational design, digital manufacturing and robotics in architecture. From 2012 – 2015 he has been TT - assistant professor at the KTH Stockholm. From 2008 – 2011 he has been a guest professor at Staedelschule Architecture Class (SAC) and worked with the engineering office Bollinger + Grohmann in Frankfurt. In 2008 Oliver Tessmann received a doctoral degree at the University of Kassel. His work has been published and exhibited in Europe, Asia and the US.

SERBAN BODEA

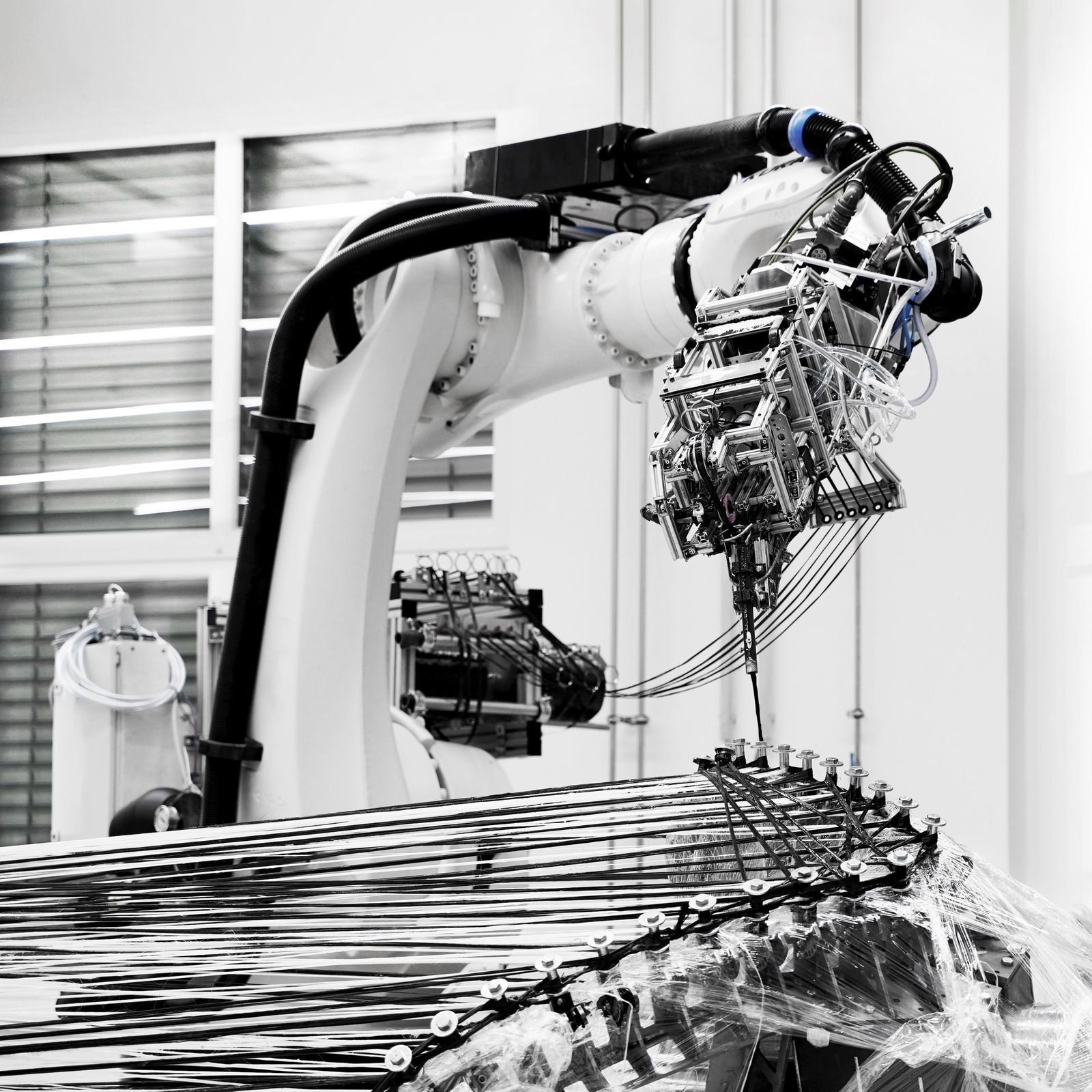

We are witnessing a time when lightweight architecture begins to tap the realm of composite materials in search for new forms, high performance, and material savings. At the same time robotic fabrication has matured from speculative applications to an area of research promising to disrupt entire industries in and around the built environment. Recent developments in design and manufacturing methods for technical and natural fiber-reinforced polymers at the University of Stuttgart are transforming the architecture and design of lightweight structures as much as they affect their engineering and construction. In particular, Coreless Filament Winding now enables mass customization of largescale loadbearing components but requires a particular approach to design and engineering that has outgrown its biomimetic beginnings.

Bio

Serban Bodea is a Romanian-born architect with expertise in computation and automation for lightweight architecture. He holds a Master’s Degree from TUDelft. Since 2017 he has been pursuing his PhD at the Institute for Computational Design and Construction (ICD) at the University of Stuttgart. There, Serban studied Fibrous Morphologies, conducting interdisciplinary research on the coreless filament winding of natural and technical fiber reinforced polymers. Within this context, he contributed to automated composite construction, verifying his Doctoral research through projects such as the award-winning BUGA Fibre Pavilion (2019) and the ITECH LivMatS Pavilion (2021). In August 2021, Serban joined the Block Research Group at the ETH Zurich as a post-doctoral researcher in the NCCR Digital Fabrication within the “Lightweight flexible formworks” research stream. He is currently involved in teaching Computational Structural at ETH and oversees research projects involving flexible formwork systems for thin reinforced concrete grid-shells for academia-industry knowledge transfer.

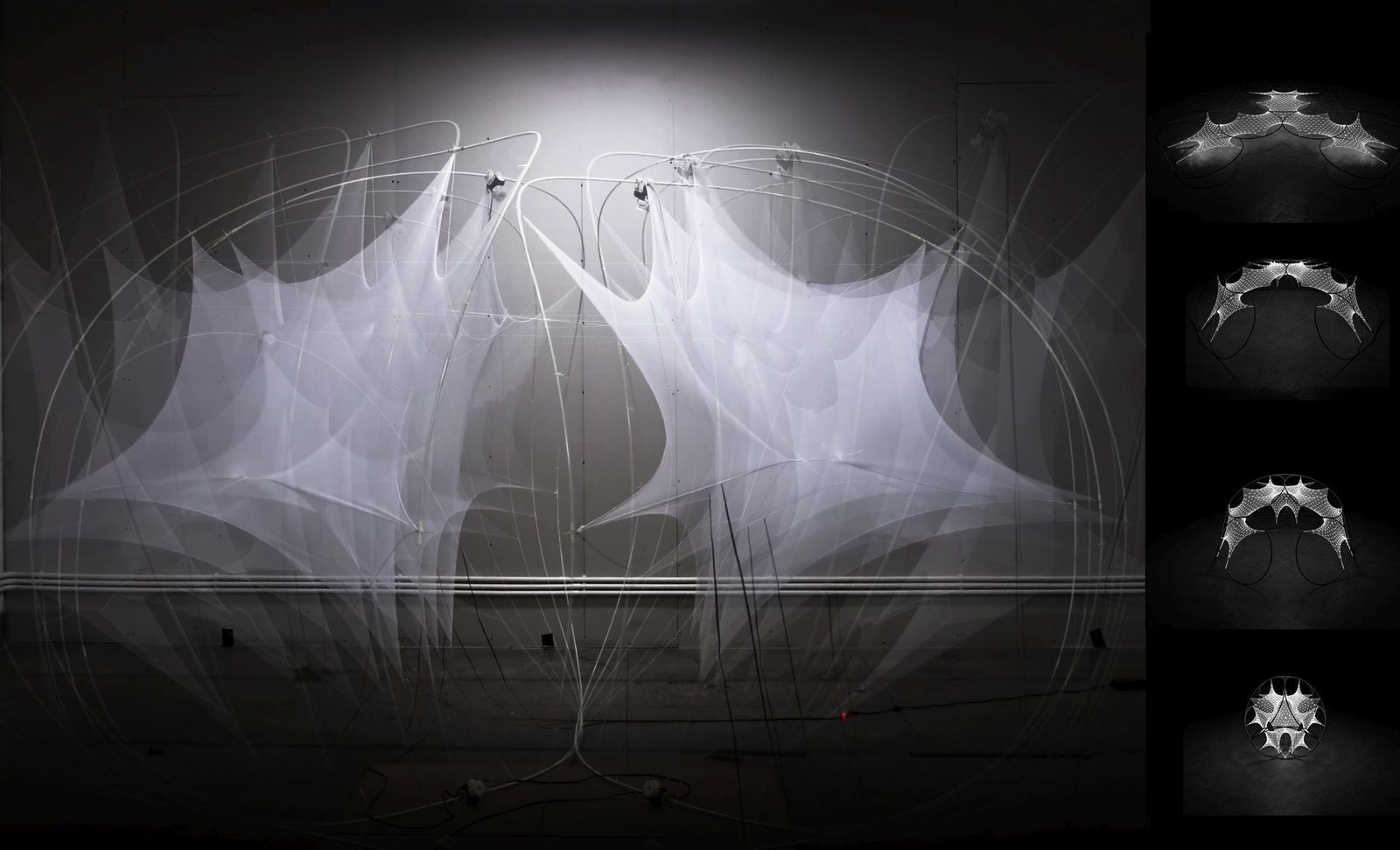

VALENTINA SOANA

Valentina Soana will present a body of research projects that explore the potential of robotic systems, lightweight structures and shape-changing materials in architecture and design. Throughout her career Valentina has worked at the intersection of engineering, art and architecture, developing a series of novel adaptive material and structural systems that can achieve multiple states of equilibrium. These robotically controlled systems leverage material behaviours, such as elastic deformations, responding to changing human, environmental and structural conditions.

Valentina’s research has focused on the development of novel methods to design and control these continuously changing material and structural systems. At a conceptual level, this research explores the role of robotics in architecture, moving beyond their role as tools, towards the notion of robotic spaces, structures and building systems. This approach opens new interaction scenarios between human, material and machine systems.

Bio

Valentina Soana is a roboticist, designer and researcher working at the intersection of architecture, engineering and art. Her research focuses on the development of adaptive lightweight robotic structures that leverage material properties to achieve multiple states. Currently, Valentina is a Lecturer at the Bartlett School of Architecture and a Doctoral Researcher in soft robotics and lightweight structures at the Department of Mechanical Engineering at the University College London. She received a Master of Architecture from KTH Stockholm and a Master of Science (ITECH) from the University of Stuttgart, both with Distinction. Valentina has worked as an architectural designer, researcher and academic at architectural firms and universities in the US, Europe and New Zealand. Her work has been published and exhibited internationally, most recently at the Venice Architecture Biennale.

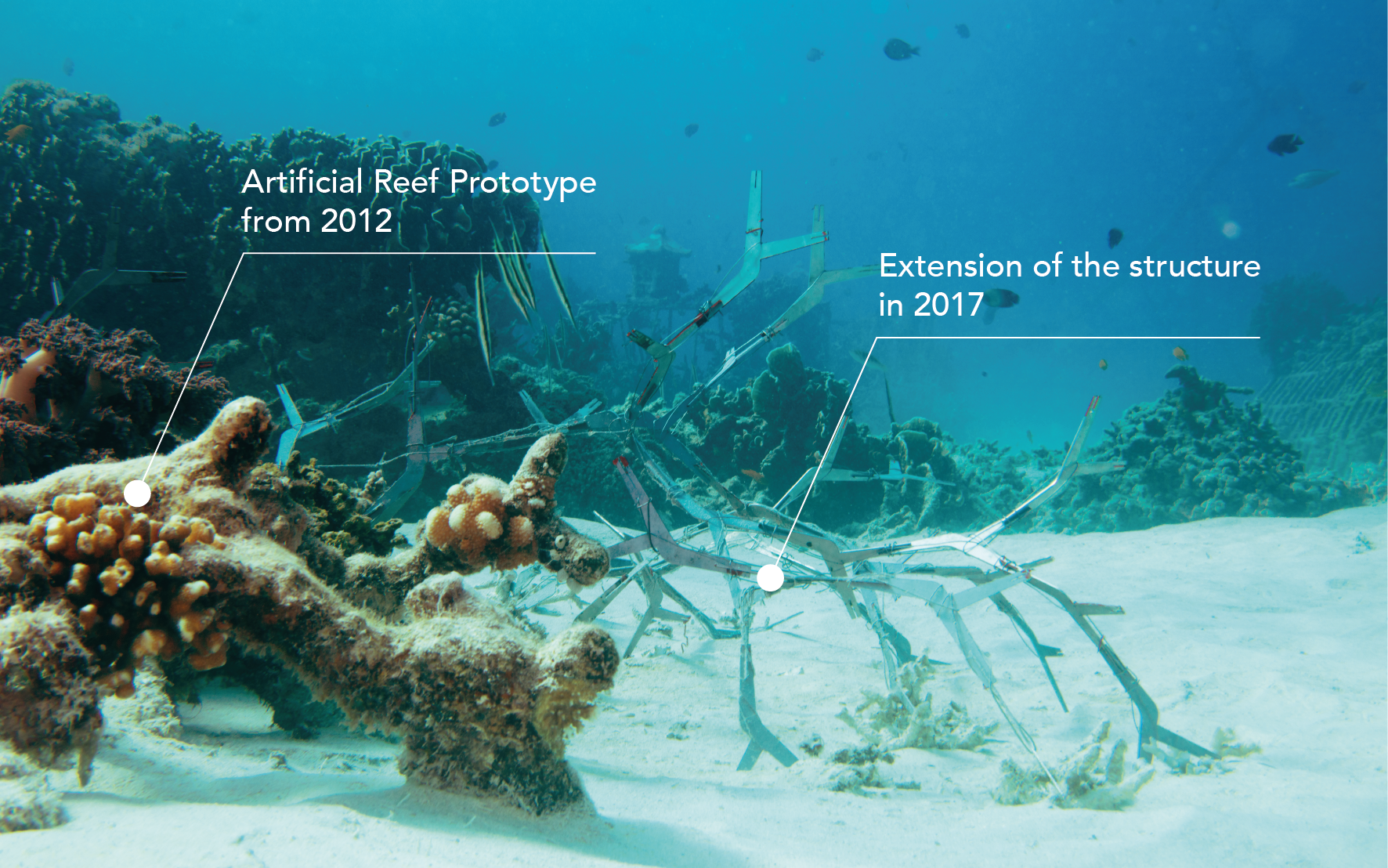

VERENA VOGLER

Computational design approaches for artificial ecosystem regeneration

The presentation will introduce a new Framework for Artificial Coral Reef Design which includes computational design, underwater monitoring, analysis and simulation methods based on real-world artificial reef prototypes in Indonesia, as well as front-end tools for design and monitoring.

Bio

Verena Vogler joined the McNeel team in 2014. It is a software company that develops Rhino and Grasshopper. She is responsible for the R&D department that participates as an industrial partner (SME) in Horizon 2020 research projects funded by the European Commission. In these projects, Rhino is used as an open development platform for technological innovation.