Projects

- ArchiSpace: Space architecture in analogue environments

- Robotic Terrain Mapping

- Discretized and Circular Design

- CV- and HRI-supported Planting

- Lunar Architecture and Infrastructure

- Robotic Drawing

- Rhizome 2.0: Scaling-up of Rhizome 1.0

- Rietveld Chair Reinvented

- Cyber-physical Furniture

- Rhizome 1.0: Rhizomatic off-Earth Habitat

- D2RP for Bio-Cyber-Physical Planetoids

- Circular Wood for the Neighborhood

- Computer Vision and Human-Robot Interaction for D2RA

- Cyber-physical Architecture

- Hybrid Componentiality

- 100 Years Bauhaus Pavilion

- Variable Stiffness

- Scalable Porosity

- Robotically Driven Construction of Buildings

- Kite-powered Design-to-Robotic-Production

- Robotic(s in) Architecture

- F2F Continuum and E-Archidoct

- Space-Customizer

100 Years Bauhaus Pavilion

Year: 2017-2019

Project leader: Henriette Bier

Project team: Henriette Bier, Sina Mostafavi, Arwin Hidding, Vera Laszlo, and MSc 1-4 students

Collaborators / Partners: DIA

Funding: 60K

This project has been funded by DIA and builds up on 2 years of studies implemented with TUD and DIA students. It involves explorations in the Design-to-Robotic-Production-Assembly and -Operation (D2RPA&O) of the 100 Years Bauhaus Pavilion (100YBP). Bauhaus envisioned architecture as Gesamtkunstwerk, incorporating all or many art forms. It influenced the 20th century’s Modernist architecture, which was based on new technologies of construction, particularly the use of glass, steel, and reinforced concrete; and upon the rejection of traditional neoclassical and Beaux-Art styles of the 19th century. The 100 years Bauhaus celebration brings about the opportunity to reflect on the influence of new technologies in the 21st century in particular artificial intelligence, robotics, and 3D printing on architecture. The proposed robotically produced structure employs subtractive and additive 3D printing technologies. Furthermore, it embeds artificial intelligence at the level where sensor-actuators such as light dependent resistors, infrared distance sensors, pressure sensors, etc. informing LED lights, speakers, projectors, etc. in order to allow users to customize operation and use of the pavilion. These will allow adaptation of the built environment to variable environmental conditions and changing user needs.

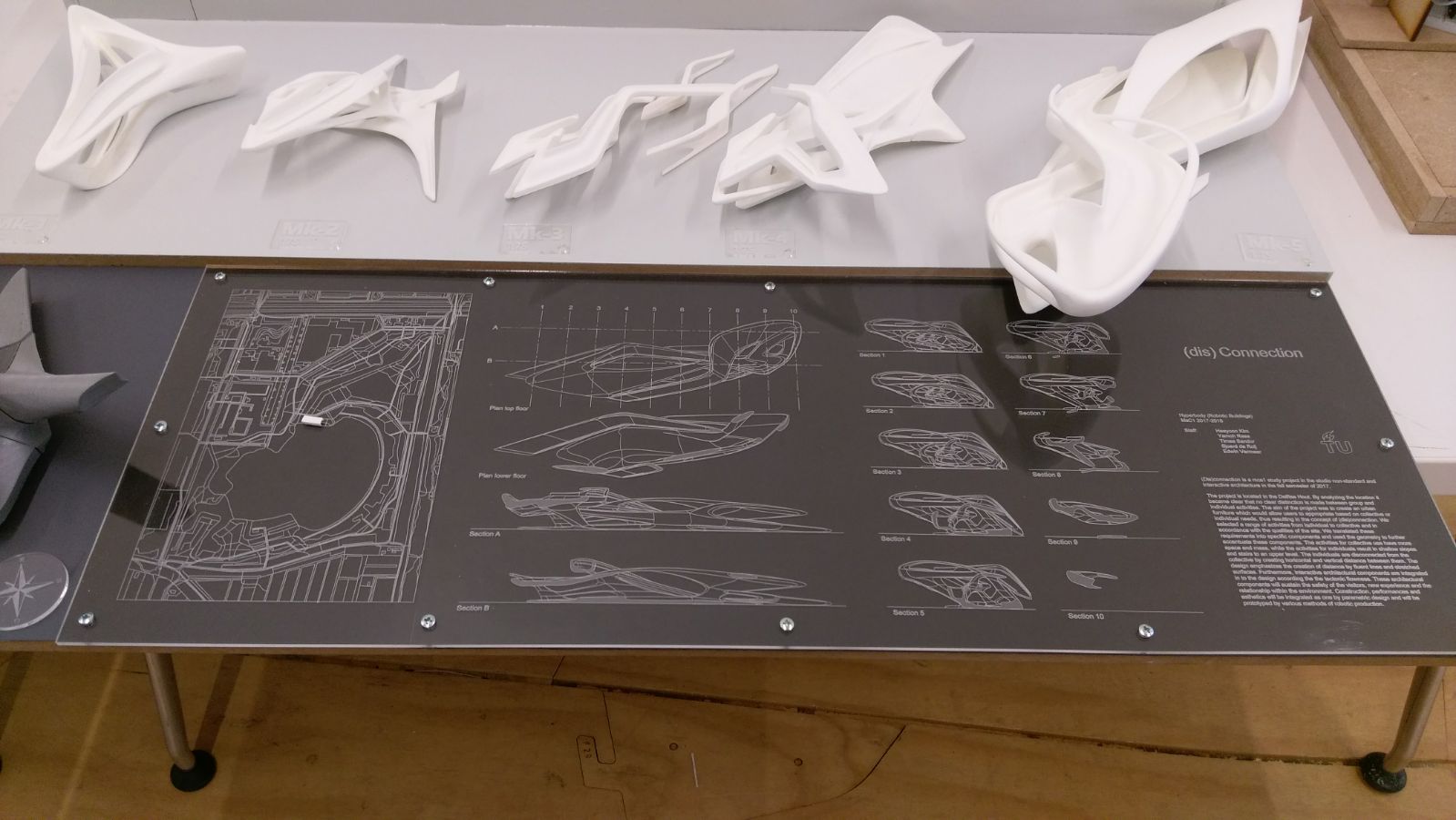

Fig. 1: Iterative design process

Several projects and various iterations were developed using Design-to-Robotic-Production-Assembly and -Operation (D2RPA&O) methods. For instance, by taking advantage of the 21st century advancement and by reusing plastic in architecture, a pavilion has been developed. Design possibilities using reclaimed plastic artefacts were explored by testing their structural stability and robotically modifying them in order to create the pavilion. While the design conceptualization started with the reclaimed material and the analysis of its potential, the digital workflow involved generative and performance- driven design, structural optimization and geometry generation for robotic fabrication.

Fig. 2: Circular plastics pavilion for the TU Delft campus

If Bauhaus was influenced by the 2nd Industrial Revolution involving standardization and industrialization, which took place from the late 19th century until the early 20th century, today¹s architecture is influenced by the 3rd and 4th industrial revolutions. The 3rd involved a shift from mechanical and analogue electronic technology to digital electronics, while the 4th is focused on robotics, IoT, CpS, and AI. They both push the development of automation wherein CpS monitor physical processes via digital twins of the physical world and make decentralized decisions. Over the IoT, CpS communicate and cooperate with each other and with humans in real-time, which is main goal of the Industry 4.0.

Movie 1: Simulation of robotic prototyping for the circular plastics pavilion

The architecture that emerges from such D2RPA&O processes is not standardized, modular, and repetitive as the Bauhaus promoted. Due to the available Industry 2.0 approaches architecture becomes customized, componential, and variable. Furthermore, this architecture is adaptive, responding through sensor-actuators to environmental and users¹ needs. While architecture in the age of robotic building increasingly relies on human-robot collaboration, architects and constructors are slow in embracing these new technologies. These technologies have, however, the potential to improve not only architecture and architectural practice but also the whole automation ecosystem, wherein customers may purchase online customizable designs using an automated marketing platform that puts the D2RPA&O plant in action. Furthermore, spatial and environmental adaptation via WSAN accommodates users¹ needs and addresses requirements for material- and energy-efficiency.

Movie 2: Robotic prototyping of node for circular plastics pavilion