Projects

- ArchiSpace: Space architecture in analogue environments

- Robotic Terrain Mapping

- Discretized and Circular Design

- CV- and HRI-supported Planting

- Lunar Architecture and Infrastructure

- Robotic Drawing

- Rhizome 2.0: Scaling-up of Rhizome 1.0

- Rietveld Chair Reinvented

- Cyber-physical Furniture

- Rhizome 1.0: Rhizomatic off-Earth Habitat

- D2RP for Bio-Cyber-Physical Planetoids

- Circular Wood for the Neighborhood

- Computer Vision and Human-Robot Interaction for D2RA

- Cyber-physical Architecture

- Hybrid Componentiality

- 100 Years Bauhaus Pavilion

- Variable Stiffness

- Scalable Porosity

- Robotically Driven Construction of Buildings

- Kite-powered Design-to-Robotic-Production

- Robotic(s in) Architecture

- F2F Continuum and E-Archidoct

- Space-Customizer

Rietveld Chair Reinvented

Year: 2023

Project leader: Henriette Bier

Project team: Henriette Bier, Arwin Hidding, Vera Laszlo, Giuseppe Calabrese and Mohammed Hassen

Collaborators / Partners: TU Library (Vincent Cellucci), Intric (Arwin Hidding) and Design Panel (Henk Antonides)

Funding: 15K

Dissemination: Re-reinterpretation, Rietveld Raakt

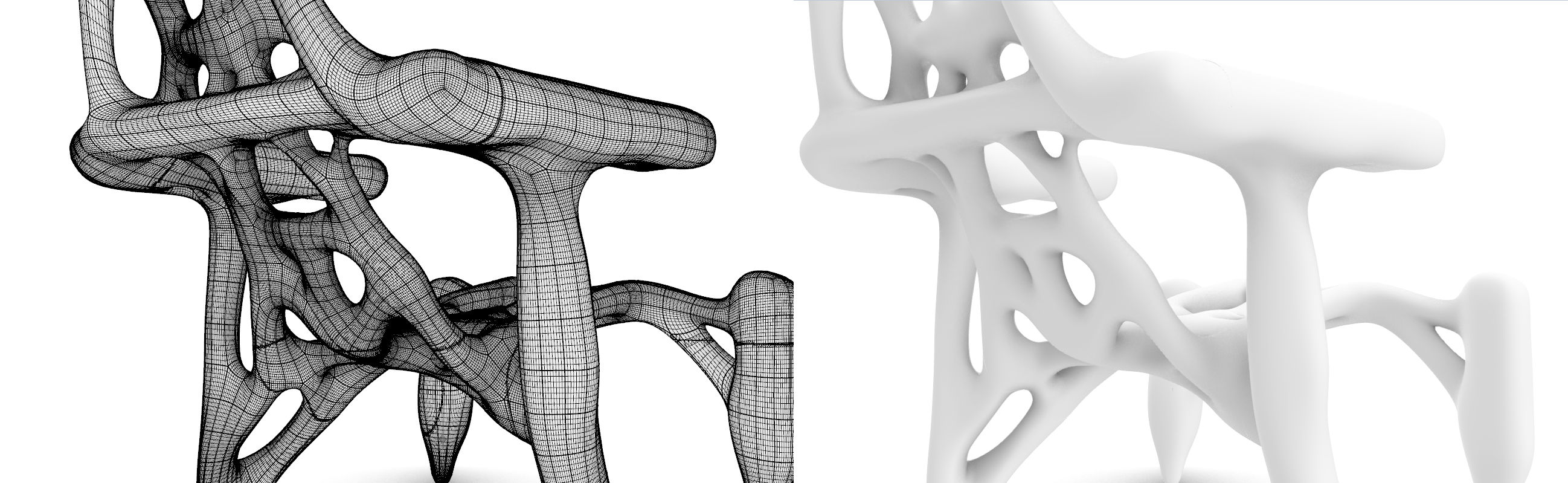

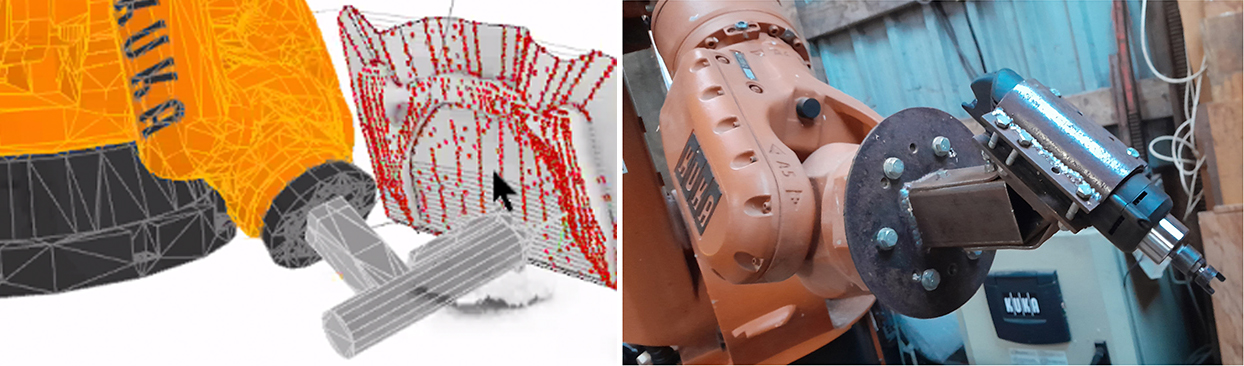

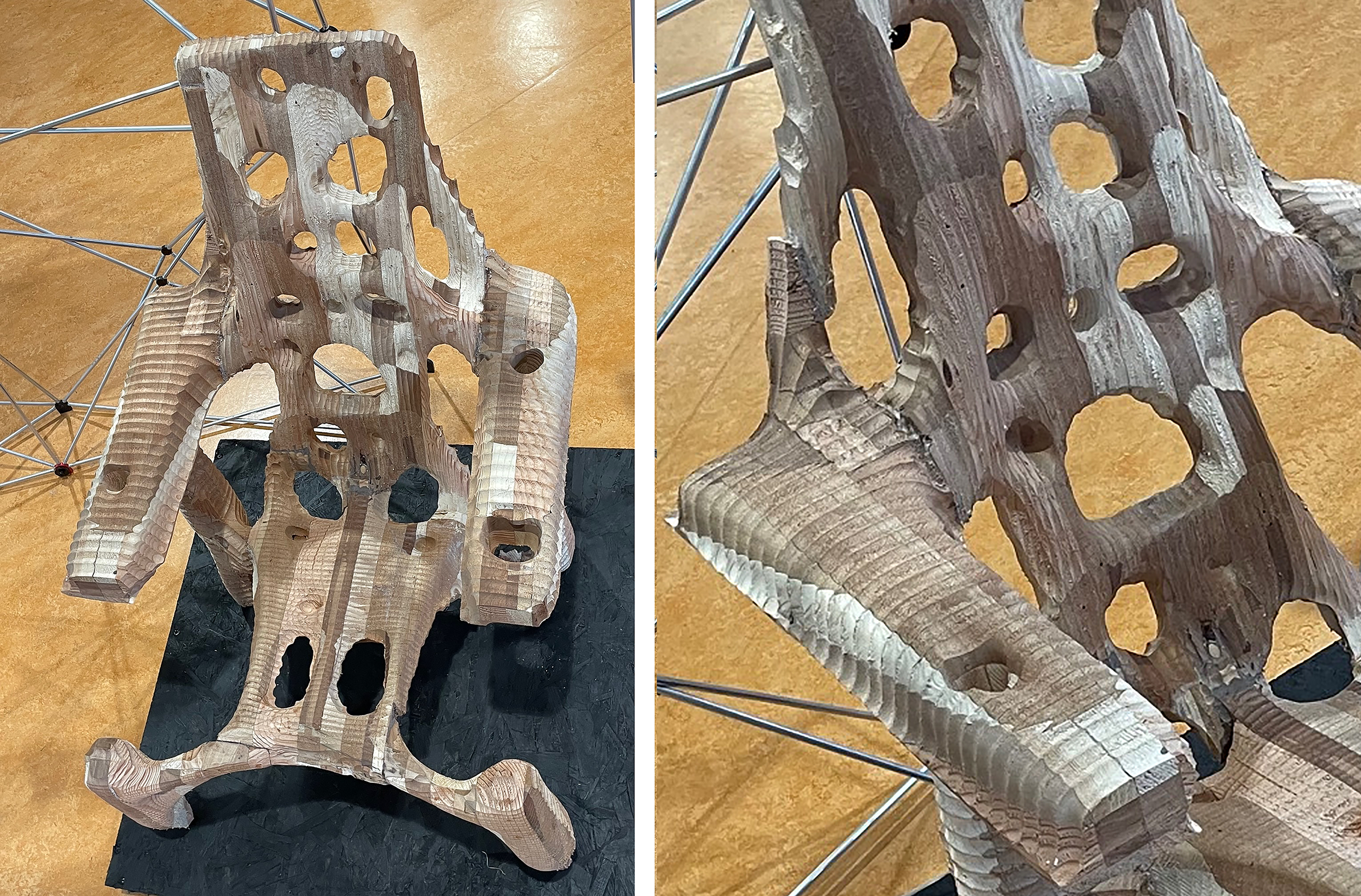

Initiated by the TU Library, Rietveld’s chair is reinvented to meet today’s architectural challenges and technical requirements. As such the chair with its original geometry is first subjected to topology optimization. Then reclaimed wood boards that are laminated are robotically milled creating a skeleton that will at a later stage accommodate cushioning and sensor-actuators for local heating or cooling (possibly using Peltier elements) and lighting.

This study is part of the Redesign Rietveld exhibition at the TU Delft library (from mid-Feb until May) which has 60 models that are all Rietveld reinterpretations serving as an inspiration to a student competition: https://www.tudelft.nl/evenementen/2023/library/redesign-rietveld-chairs-student-design-competition.

In the first iteration, material is roughly removed from the blocks of laminated wood using a 25 mm diameter milling head. In the follow-up second iteration (work in progress) high-res milling is implemented with a milling head of 8 mm on the seating side and lower-res milling with a 15 mm milling head on the backside. Additional 3D-printed cushions and sensor-actuators will be fitted in the third iteration in order to increase comfort of the chair.