Projects

- ArchiSpace: Space architecture in analogue environments

- Robotic Terrain Mapping

- Discretized and Circular Design

- CV- and HRI-supported Planting

- Lunar Architecture and Infrastructure

- Robotic Drawing

- Rhizome 2.0: Scaling-up of Rhizome 1.0

- Rietveld Chair Reinvented

- Cyber-physical Furniture

- Rhizome 1.0: Rhizomatic off-Earth Habitat

- D2RP for Bio-Cyber-Physical Planetoids

- Circular Wood for the Neighborhood

- Computer Vision and Human-Robot Interaction for D2RA

- Cyber-physical Architecture

- Hybrid Componentiality

- 100 Years Bauhaus Pavilion

- Variable Stiffness

- Scalable Porosity

- Robotically Driven Construction of Buildings

- Kite-powered Design-to-Robotic-Production

- Robotic(s in) Architecture

- F2F Continuum and E-Archidoct

- Space-Customizer

Circular Wood for the Neighborhood

Year: 2020-2022

Project leader HvA: Marta Male-Alemany

Project partner TUD / Leader of D2RP work package: Henriette Bier

Project team TUD: Henriette Bier, Arwin Hidding, Max Latour, Vera Laszlo

Collaborators / Partners: Ymere, Rochdale, Platform 31, Gemeente Amsterdam, Metabolic, TNO, Lenferink, Rutges, GP Groot, Ter Steege Bouw en Advies

Funding: 300K

Dissemination: DDW 2020

The project has been initiated by HvA with the objective to identify opportunities for wood reuse through the use of advanced digital production technologies, and develop related implementation strategies for public organisations, in particular housing corporations and municipalities. Strategies include concrete proposals on how to: a) collect and process wood waste from residential buildings; b) add value to reclaimed wood by means of digital production; c) increase tenant involvement and acceptance for waste wood collection and circular reuse; d) create impactful applications for a circular economy.

The project explores the availability and nature of wood waste from residential buildings, and identifies opportunities for reuse. Evidence from preceding projects shows that digital production enables turning urban waste into meaningful circular products, and facilitates the (local) fabrication of unique prototypes and full scale applications, which can become tangible demonstrations of circularity for public organisations.

Fig. 1: Packing/gluing procedure of circular wood (left) and robotic milling procedure (middle and right) / Images courtesy of David 't Lam, Cameron Roeten, Jakob de Konink (HvA) and Max Latour (TUD)

The first identifies the nature of residential wood waste (volume, type, application) from past case projects of housing corporations Ymere and Rochdale. Their upcoming renovation plans are also evaluated, to identify resources and hotspots for future implementations. Finally, the development of a KPI framework helps determine the impact of specific applications. The second work package explores what applications can be conceived, given the available wood and digital production tools. In the third work package case studies are carried out for actual projects of the housing corporations, showing the potential of digital production and providing insights on the viability of concrete applications. Physical prototypes are used as conversation pieces to involve tenants and increase their acceptance for circular applications. In the fourth work package all findings are combined in a set of implementation strategies.

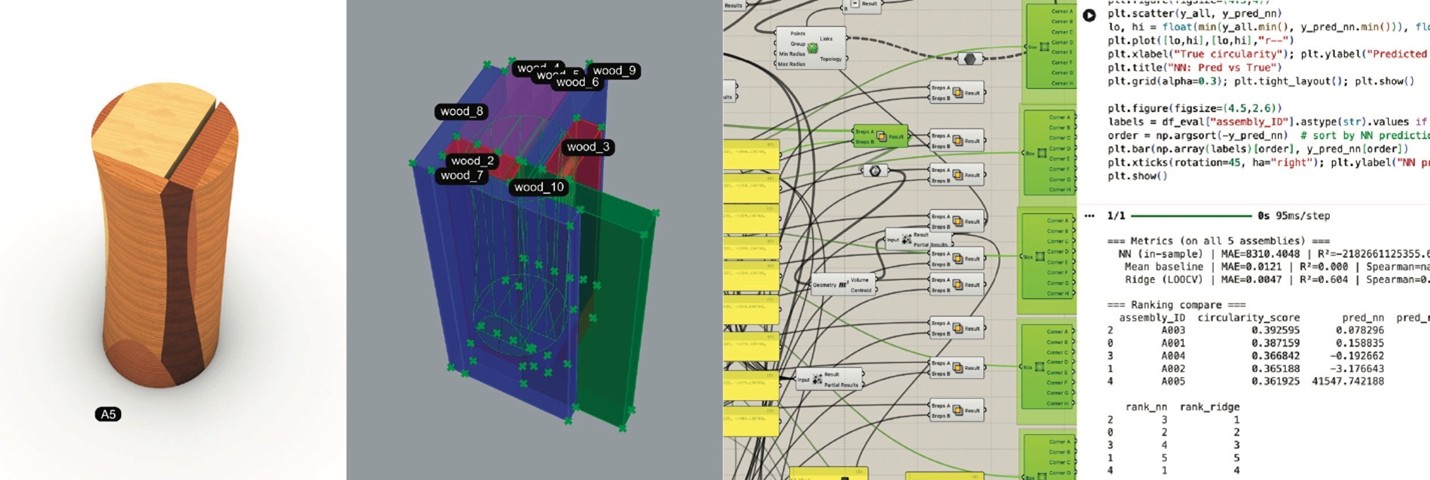

As part of the project, research in Design-to-Robotic-Production (D2RP) is implemented at TUD on designs that explore biomimetic architecture in the times of the 4th industrial revolution as an architectural intervention in a building from the 2nd industrial era (Mov. 1). The main architectural intervention is a new atrium for the historic building. The computational design relies on biomimetic simulations, structural and robotic path optimizations. By using reclaimed wood elements that are glued and milled into larger curvilinear components connected to topologically optimized 3D printed metal nodes the project not only addresses the current quest for circularity but also takes advantage of the most recent robotic technology developed at TU Delft and HvA (Mov. 2).

Mov. 1: Componential Hybridity

Mov. 2: Robotic milling procedure / Images courtesy of David 't Lam, Cameron Roeten, Jakob de Konink (HvA) and Max Latour (TUD)

Within this broader agenda, the cascading principle for the reuse of wood extends material lifespans by enabling the transformation of wood from higher- to lower-value applications without leaving the circular loop, thereby safeguarding biogenic carbon stored within the material and contributing to decarbonization by delaying carbon release. The implementation requires systematic management of heterogeneous reclaimed wood stocks, as materials undergo successive processes of disassembly, re-design and -deployment. These processes require computational and data-driven workflows capable of coordinating information across design and materialization stages, ensuring informed and consistent decision-making within low-CO2 circular strategies.

An AI-supported design method has been developed to generate and evaluate alternative design assemblies based on multiple criteria, including material usage, feasibility for robotic milling, and aesthetic qualities. Complex geometries and material attributes are translated into structured datasets suitable for machine learning through the coordinated use of two computational environments: a visual–geometric environment (Rhino/Grasshopper), employed for designing, parameterizing, and evaluating spatial assemblies and a text-based environment (Python in Visual Studio Code and Google Colab), applied in data processing, modelling, and training. Data extracted from Grasshopper—including identifiers (e.g., assembly ID), numerical descriptors (e.g., coordinates), categorical attributes (e.g., wood type), and relational features (e.g., adjacency to other components)—are exported as structured Comma-Separated Values (CSV) files for AI training. Relevant AI models, such as Deepset, Graph Neural Network, and sets of Generative AI (GenAI), are explored to determine whether designer-like reasoning and decision-making logics can be reproduced. By linking material properties, geometric constraints, and fabrication requirements within AI- and robot-assisted pipelines, the research advances circular design-to-construction workflows that support informed, adaptive, and scalable reuse of reclaimed wood through the automated selection, matching, and spatial arrangement of reclaimed wood pieces.

Several reviews are scheduled regularly with partners in order to not only share developed knowledge but also discuss potential and challenges of implemented studies in order to coordinate further steps in relationship to the insights: